Tire walls are made by laying tires in staggered courses like bricks or concrete blocks. Each tire is filled with compacted earth, so that it becomes a rammed earth brick encased in steel belted rubber, about 95% compacted.

A pounded tire weighs over 300 pounds, therefore, all tires are pounded in place and are NOT moved after the tire is fully pounded and leveled.

The tires are set on leveled undisturbed ground and pounded in place using a sledge hammer. Each tire takes about three or four wheel-barrows of dirt. The tires are pounded level in all directions.

Scrap cardboard or empty cement bags are used to fill in the holes in the tires and make them temporarily contain the earth on all courses other than the first course which is flat on the ground and plastic is used. The first course gets a double layer of 6 mil plastic in the bottom of each tire. Since both sides of the tire wall will eventually be buried or covered by plaster, the cardboard could decompose without affecting the rammed- earth.

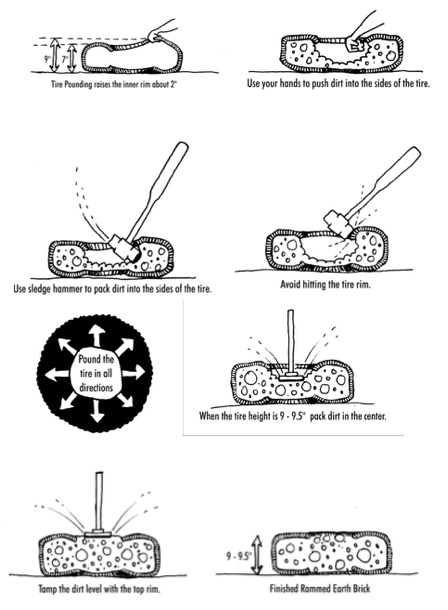

How to pound a tire:

- Layout tires – pound in place.

- Place cardboard or plastic in the bottom of each tire.

- Stuff tires with dirt by hand.

- Pound dirt into tire casing with an 8 lb. sledgehammer

- Tamp the dirt in the middle of the tire.

- Level the tire in all directions and to the other tires nearby.

Tire Pounding Details

What size tires to use where?

Large sized tires are used at the bottom of the wall, smaller sized tires are used at the top of walls. 16s (a large tire size) with plastic in the bottom are used for the first course of tires.

- 23516sforcourse1,2and3

- 235 15s for course 4 and 5

- 225 15s for course 6 and 7

- 215 15s for course 8 and 9

- 305 15s for course 10 (14s can be used on the top course)

Important: Large sized tires at the bottom of the wall, smaller sized tires at the top of walls.

Off-Grid Builders, Earthship Home Designs

Note: We design and build all over the USA and around the world.

What is an Earthship Home?

An Earthship is a type of passive solar house that is made of both natural and upcycled materials (such as earth-packed tires). Earthships can be completely off-grid or partially off-grid.

Earthships can be built in any part of the world, in any climate (with a permit) and still provide electricity, potable water, contained sewage treatment and sustainable food production.

Earthships are thermal mass homes first, passive solar homes second.

Whatever temperature goes into an Earthship, it will hold… and since it is also a Passive Solar House, it is also very tight and interacts only with the sun and the earth for heating and cooling, providing stable comfort year round in any climate. This results in being able to provide a sustainable home on property that may not be situated to the ideal of 13.5 degrees east of south.

Leave A Comment